ASME B16.5 150# 8 NPS SLIP ON RF A105 FLANGE

JIS/KS 5K, 10K, 16K, 20K, 30K

UNI 2253/2254/2276-2278/2281-2284/6083/6

Flange Standard

ANSI B16.5/ B16.47/ B16.36/ API605, 6A, 6B/ MSS SP44/ AWWA C207

DIN 2527/ 2528/ 2561/ 2565/ 2566/ 2573/ 2576/ 2627/ 2630/ 86029/ 86030 etc.

BS 4504 PN16/PN40, BS10 TABLE E/TABLE D

JIS/KS 5K, 10K, 16K, 20K, 30K

UNI 2253/2254/2276-2278/2281-2284/6083/6084/6089-6093

GOST 12820/12821

American Series: CLASS 150, CLASS 300, CLASS 400, CLASS 600, CLASS 900, CLASS 1500, CLASS 2500

European Series: PN 2.5, PN 6, PN 10, PN 16, PN 25, PN 40, PN 63, PN 100, PN 160, PN 250, PN 320, PN 400

Flange Facing Types:

Flat Face (FF), Raised face (RF), groove (G), female(F), ring joints face(RJ)

Material:

Carbon steel (ASTM A105 A350LF2 LF3 A694 A36 Q235 A3 20# 45# 20Mn 16Mn Q345 etc.);

Stainless steel (SS316, SS304, SS316L, SS304L, SS321 SS317 F51 F53 316Ti etc.);

Alloy steel (A182F5 A182F11 F22 15CrMo 30CrMo 35CrMo 40CrMO 42CrMo 4130 4140 etc.)

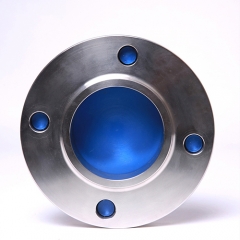

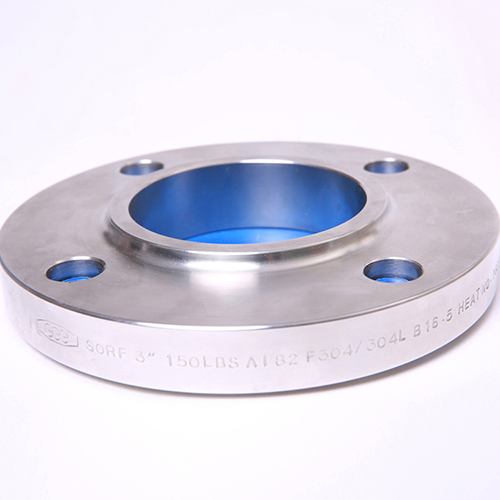

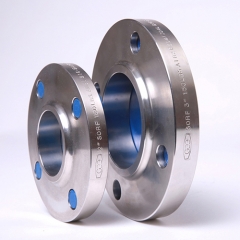

Raised Face (RF)

The Raised Face flange is the most common type used in process plant applications, and is easily to identify. It is referred to as a raised face because the gasket surfaces are raised above the bolting circle face. This face type allows the use of a wide combination of gasket designs, including flat ring sheet types and metallic composites such as spiral wound and double jacketed types.

The purpose of a RF flange is to concentrate more pressure on a smaller gasket area and thereby increase the pressure containment capability of the joint. Diameter and height are in ASME B16.5 defined, by pressure class and diameter. Pressure rating of the flange determines the height of the raised face.

The typical flange face finish for ASME B16.5 RF flanges is 125 to 250 µin Ra (3 to 6 µm Ra).

Ring-Type Joint (RTJ)

The Ring Type Joint flanges are typically used in high pressure (Class 600 and higher rating) and/or high temperature services above 800°F (427°C). They have grooves cut into their faces which steel ring gaskets. The flanges seal when tightened bolts compress the gasket between the flanges into the grooves, deforming (or Coining) the gasket to make intimate contact inside the grooves, creating a metal to metal seal.

An RTJ flange may have a raised face with a ring groove machined into it. This raised face does not serve as any part of the sealing means. For RTJ flanges that seal with ring gaskets, the raised faces of the connected and tightened flanges may contact each other. In this case the compressed gasket will not bear additional load beyond the bolt tension, vibration and movement cannot further crush the gasket and lessen the connecting tension.